Introduction

Compressed gas storage is essential for various industrial, medical, and recreational applications. Among the gases commonly stored under high pressure, nitrogen plays a crucial role due to its wide range of uses in manufacturing, research, and safety applications. One of the best ways to store high-pressure nitrogen is using carbon fiber composite cylinders. These cylinders offer a lightweight, durable, and high-strength alternative to traditional steel tanks. But is it safe and practical to use carbon fiber cylinders for storing nitrogen at pressures up to 300 bar? Let’s explore this in detail.

Understanding Carbon Fiber Composite Cylinders

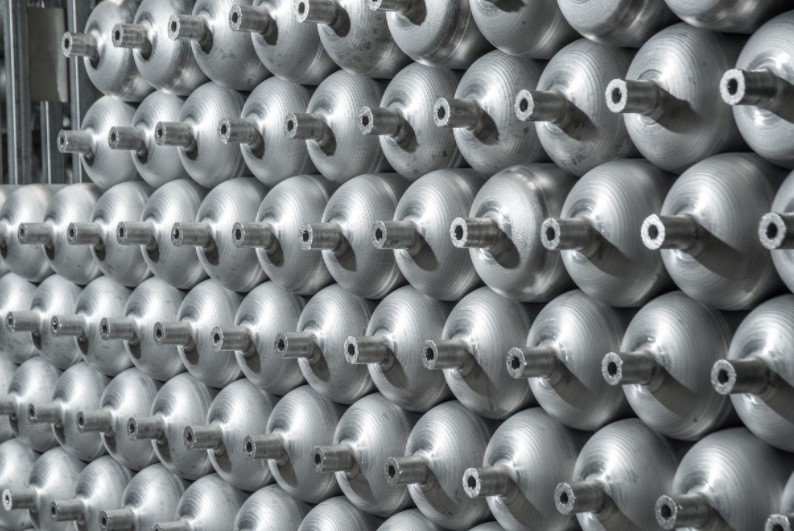

Carbon fiber composite cylinders are advanced pressure vessels made from a combination of carbon fiber and resin, typically wrapped around an aluminum or plastic liner. Compared to traditional steel cylinders, these tanks are significantly lighter while maintaining high strength and durability. Their key advantages include:

- Lightweight Structure: Carbon fiber cylinders weigh much less than steel cylinders, making them easier to handle and transport.

- High Strength-to-Weight Ratio: Carbon fiber provides exceptional tensile strength, allowing these cylinders to withstand high pressures without adding excessive weight.

- Corrosion Resistance: Unlike steel cylinders, carbon fiber composites do not rust, making them suitable for long-term use in various environments.

- Longer Service Life: Properly maintained carbon fiber cylinders can last many years, reducing replacement costs over time.

Can Carbon Fiber Cylinders Hold Nitrogen at 300 Bar?

Yes, carbon fiber composite cylinders can safely store nitrogen at 300 bar (or even higher) if they are designed and tested for such pressures. The key factors that ensure safety and functionality include:

- Cylinder Design & Material Strength

- Carbon fiber cylinders are specifically engineered to handle high-pressure gases. They undergo rigorous testing to ensure their structural integrity under extreme conditions.

- Most high-pressure carbon fiber cylinders come with a design safety factor, meaning they are built to withstand pressures well above their working limit.

- Gas Compatibility

- Nitrogen is an inert gas, meaning it does not react with the cylinder material, reducing the risk of chemical degradation or internal corrosion.

- Unlike oxygen or other reactive gases, nitrogen does not pose an oxidation risk, further enhancing the longevity and safety of carbon fiber cylinders.

Safety Considerations When Using Carbon Fiber Cylinders for Nitrogen

While carbon fiber cylinders are a reliable option for storing high-pressure nitrogen, proper usage and maintenance are essential for safety. Here are some key safety practices:

- Regular Inspections: Cylinders should be visually inspected for any signs of damage, such as cracks, dents, or delamination of the fiber layers.

- Pressure Regulation: Always use a suitable pressure regulator when dispensing nitrogen to avoid sudden pressure surges that could compromise the cylinder’s integrity.

- Proper Handling & Storage:

- Store cylinders in a cool, dry place away from direct sunlight and extreme temperatures.

- Secure cylinders in an upright position to prevent accidental falls or damage.

- Hydrostatic Testing:

- Most high-pressure cylinders require periodic hydrostatic testing to ensure they can still safely hold gas at the designated pressure.

- Check the manufacturer’s guidelines for the testing interval, which is typically every 3 to 5 years.

- Avoid Overfilling: Never exceed the cylinder’s rated pressure, as this can weaken the structure over time and increase the risk of failure.

Applications of High-Pressure Nitrogen Storage in Carbon Fiber Cylinders

The ability to store nitrogen at 300 bar using carbon fiber cylinders has significant benefits in various industries:

- Industrial Use: Many manufacturing processes require high-purity nitrogen for inerting, purging, and pressurization applications.

- Medical Applications: Hospitals and laboratories use nitrogen for cryogenic preservation and other specialized applications.

- Scuba Diving & Firefighting: High-pressure cylinders are used in rebreathers and breathing apparatuses for safety and emergency response.

- Automotive & Aerospace: Nitrogen is used in tire inflation, shock absorbers, and aircraft systems, where lightweight and durable storage solutions are crucial.

Conclusion

Carbon fiber composite cylinders are a safe, efficient, and practical solution for storing nitrogen at pressures up to 300 bar. Their lightweight design, high strength, and resistance to corrosion make them a superior alternative to traditional steel cylinders. However, ensuring compliance with safety standards, regular maintenance, and proper handling are essential to maximize their longevity and safety. As industries continue to demand high-performance gas storage solutions, carbon fiber cylinders will remain a key component in meeting these needs.

Post time: Mar-04-2025