When customers buy carbon fiber air tanks for applications like SCBA (Self-Contained Breathing Apparatus), quality and durability are paramount. Occasionally, visual discrepancies in the aluminum liner surface of these tanks can raise concerns. A recent interaction with a customer provides a useful case study to discuss what these marks mean, their origin, and their impact on the cylinder’s functionality and safety.

The Concern: Marks That Resemble Corrosion

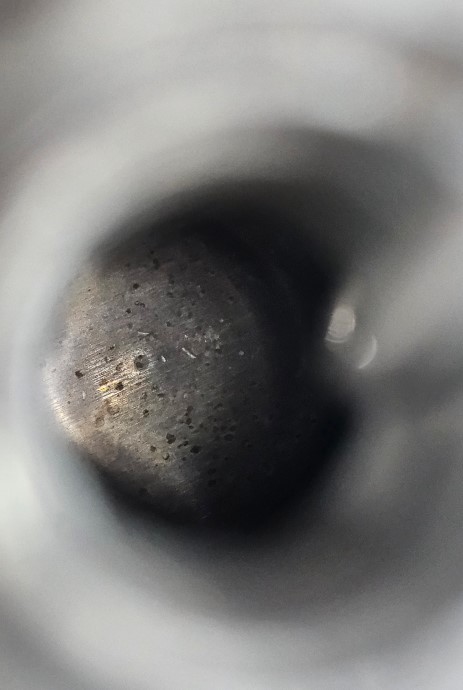

The customer reported finding marks that resembled corrosion on cylinders inspected. Since these cylinders were intended for certification testing, the customer sought clarification and assurance about the nature of these marks, their implications, and whether they could be avoided in the future.

Clarifying the Nature of the Marks

After consulting with our chief engineer, we confirmed that the observed marks were not corrosion but rather water stains formed during the production process. Let’s break down the explanation:

- Ultrasonic Neutral Cleaning

The aluminum liners of our carbon fiber cylinders are cleaned using an ultrasonic neutral cleaning method. This is a physical cleaning process that avoids chemical agents like acids. While effective in removing impurities, this method may leave harmless water stains after the subsequent heat treatment stage. - Formation of Protective Films

During heat treatment, any remaining water stains on the liner surface may develop into visible marks at high temperatures. However, these marks are purely cosmetic and do not affect the structural integrity or safety of the liner. In fact, the physical cleaning process creates a protective oxide film on the liner, which helps prevent corrosion over time. - Corrosion Characteristics

It’s essential to differentiate these water stains from actual corrosion. Real corrosion in aluminum alloys typically manifests as white spots or powdery residues, indicating material degradation. These are absent in our liners, confirming the marks are superficial and harmless. - Risks of Chemical Cleaning

Some manufacturers use acid pickling (chemical cleaning) to achieve a visually flawless, smooth liner surface. While this process enhances the initial appearance, it strips the surface layer of the aluminum, potentially leaving behind acid residues that are not visible to the naked eye. Over time, these residues can cause gradual corrosion, compromising the liner’s durability and shortening the lifespan of the cylinder.

Why Our Cleaning Process Is Safer

While our cleaning process may result in minor cosmetic marks, it prioritizes long-term performance and safety:

- Chemical-Free Cleaning: By avoiding acids, we ensure no harmful residues are left on the liner.

- Enhanced Durability: The protective film formed during our process acts as a barrier against environmental factors that could cause corrosion.

- Health and Safety Assurance: Since there are no chemical residues, our liners are safer for health-critical applications like SCBA.

Customer Concerns About Aluminum Liners

It’s not uncommon for customers to associate visual marks with potential issues like corrosion, especially when the tanks are critical for life-support equipment. However, it’s vital to focus on the cylinder’s functionality and safety rather than superficial aesthetics.

How We Address These Concerns:

- Transparency

We educate our customers about our production processes, highlighting the differences between physical and chemical cleaning. By explaining the formation and impact of water stains, we reassure them about the product’s quality and safety. - Clear Identification of Corrosion

We provide clear guidance on what real corrosion looks like, empowering customers to distinguish between harmless marks and genuine issues. - Focus on Long-Term Benefits

We emphasize the long-term durability and reliability of our cleaning method compared to the risks associated with chemical cleaning.

Impact on Cylinder Performance and Health

The water stains observed in our aluminum liners have no impact on the cylinder’s performance or safety:

- Structural Integrity: The marks do not compromise the strength or pressure-holding capacity of the cylinder.

- Health Concerns: There are no adverse health effects associated with these marks, as no harmful chemicals are involved in our cleaning process.

- Cylinder Lifespan: Our cleaning process helps guarantee the liner’s lifespan by guarding against environmental degradation.

Advice for Customers

- Understand Your Product: Familiarize yourself with the manufacturing process of the cylinders you purchase. Knowing the methods used can provide clarity about any visual anomalies.

- Focus on Functionality: When inspecting cylinders, prioritize functional aspects like pressure capacity and durability over superficial appearance.

- Communicate Concerns: If you encounter unexpected marks or other issues, communicate with the manufacturer for clarification. In most cases, they can provide insights and resolutions.

Conclusion

Carbon fiber air tanks are critical components in safety equipment like SCBA. While cosmetic marks mentioned above may occasionally appear, they are a natural result of safe, chemical-free cleaning processes. These marks have no effect on the cylinder’s performance, safety, or lifespan. By prioritizing durability and safety over superficial appearance, we ensure our products meet the highest standards for demanding applications.

This case underscores the importance of transparent communication between manufacturers and customers, enabling mutual understanding and confidence in the product’s quality

Post time: Dec-11-2024