Introduction

Nanotube technology has been a hot topic in advanced material science, with claims that carbon nanotubes (CNTs) can significantly enhance the strength, durability, and performance of carbon fiber tanks. However, practical applications often show mixed results. Some manufacturers report increased mechanical properties, while others, like your lab tests, indicate little to no improvement. This article explores whether nanotube technology truly contributes to better carbon fiber tanks or if it is just a marketing-driven hype.

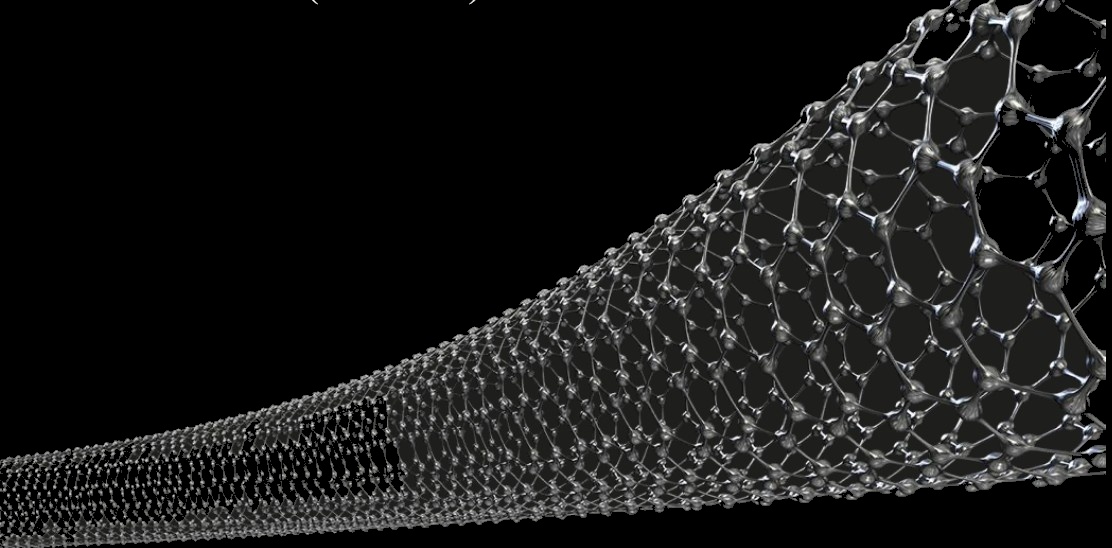

Understanding Carbon Nanotube Technology

Carbon nanotubes are cylindrical molecules consisting of rolled-up sheets of single-layer carbon atoms (graphene). They are known for their exceptional strength, high electrical and thermal conductivity, and lightweight properties. In theory, when CNTs are incorporated into carbon fiber composites, they can enhance tensile strength, improve impact resistance, and even extend the lifespan of the final product.

How Nanotubes Are Integrated into Carbon Fiber Tanks

Nanotubes can be added to the resin matrix or directly into the carbon fiber manufacturing process. The goal is to create a more reinforced composite structure by improving the bonding between the resin and the carbon fibers. Some expected benefits include:

- Increased Tensile Strength: Nanotubes are extremely strong, and if well-dispersed, they should improve the overall strength of the composite.

- Enhanced Durability: CNTs are expected to reduce microcracking, making the tank more resistant to fatigue and pressure cycles.

- Weight Reduction: By improving material strength, thinner and lighter tanks could be designed without compromising performance.

- Improved Thermal Stability: Nanotubes have excellent heat resistance, which may help in high-temperature applications.

Why Some Tests Show Little to No Improvement

Despite these theoretical advantages, many labs and manufacturers—including your own—find little noticeable performance gain. Some reasons for this include:

- Poor Dispersion of Nanotubes

- CNTs tend to clump together, making it difficult to evenly distribute them in the resin. If the dispersion is not uniform, the expected reinforcement benefits may not materialize.

- Interfacial Bonding Issues

- Simply adding nanotubes to the resin or fiber does not guarantee better adhesion. If the bonding between CNTs and the surrounding material is weak, they do not contribute to structural strength.

- Processing Challenges

- The addition of CNTs can change the viscosity of resins, making the manufacturing process more complex and potentially reducing the quality of the final product.

- Marginal Gains vs. High Costs

- Even when some improvements are observed, they may not be significant enough to justify the added cost and complexity of integrating CNTs into carbon fiber tank production.

Real-World Applications: Where It Might Work

Although CNTs may not drastically enhance traditional carbon fiber tanks used in SCBA, EEBD, or air rifles, they could still have niche applications:

- Extreme Environments: In aerospace and military applications, even slight improvements in strength or weight reduction could justify the use of CNT-enhanced tanks.

- High-Cycle Fatigue Resistance: If properly integrated, CNTs might reduce microcracking, which could benefit industries where tanks undergo frequent pressurization cycles.

- Future Research Potential: As dispersion techniques and bonding technologies improve, future applications of CNTs in carbon fiber composites might yield better results.

Conclusion: Hype or Reality?

Based on current findings, CNTs do have potential but are not yet a game-changer for carbon fiber tanks in most industrial applications. The challenges in dispersion, bonding, and cost-effectiveness make them impractical for many manufacturers. While ongoing research may eventually unlock their full potential, for now, nanotube technology in carbon fiber tanks seems to be more of an experimental enhancement rather than a must-have feature. If your tests show little benefit, it might be best to focus on more proven methods of improving tank performance rather than investing heavily in CNT integration.

Post time: Feb-24-2025