For decades, steel cylinders reigned supreme when it came to storing compressed air. However, the rise of carbon fiber technology has shaken things up. This article delves into the world of carbon fiber air cylinders, analyzing their advantages and disadvantages compared to traditional steel options. We’ll also explore the impact of different cylinder sizes and peek into the future of compressed air storage with this innovative material.

Lightweight Champion: The Allure of Carbon Fiber

The most striking benefit of carbon fiber air cylinders is their weight. Compared to their steel counterparts of the same volume, carbon fiber cylinders can be a staggering 70% lighter. This dramatic weight reduction offers several advantages:

-Enhanced Portability: For activities like scuba diving, paintball, fire rescue, or medical emergencies, lighter cylinders translate to easier carrying, improved maneuverability, and reduced user fatigue. This can be especially beneficial for extended periods of activity or situations requiring quick movement.

-Ergonomic Benefits: The lighter weight reduces strain on the back and shoulders, minimizing the risk of musculoskeletal injuries. This is particularly important for users who carry the cylinders for extended periods or those with pre-existing back problems.

-Increased Payload Capacity: Lighter cylinders allow for increased payload capacity in scenarios where multiple cylinders need to be transported. This is crucial for applications like professional diving operations or emergency response teams.

Durability with Finesse: More Than Just Light

While lightweight, carbon fiber doesn’t sacrifice strength. These cylinders are known for their impressive durability, capable of withstanding significant pressure and impact.

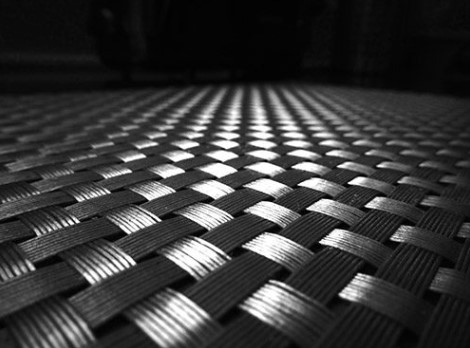

-High-Strength Construction: Carbon fibers are woven into a composite material, creating a structure that is both strong and lightweight. This allows them to handle the pressures of various gasses safely.

-Corrosion Resistance: Unlike steel, carbon fiber is immune to rust and corrosion. This eliminates a major factor that can deteriorate steel cylinders over time, potentially reducing replacement costs in the long run.

Beyond the Basics: Other Advantages to Consider

Carbon fiber air cylinders offer several additional benefits beyond weight and durability:

-Higher Pressure Ratings: Some carbon fiber cylinders can handle higher pressure ratings compared to steel. This can allow for increased gas storage capacity or the use of high-pressure systems.

-Visual Appeal: Many users appreciate the sleek and modern look of carbon fiber compared to the traditional steel aesthetic.

Different Sizes for Different Needs: Not One-Size-Fits-All

Carbon fiber air cylinders come in a range of sizes to accommodate various applications. Choosing the right size depends on several factors:

-Gas Requirements: The amount of gas needed will dictate the size of the cylinder. A recreational scuba diver might opt for a smaller, more manageable cylinder, while a professional firefighter might require a larger capacity for extended operations.

-Portability Constraints: For situations where portability is critical (e.g., hiking with medical supplies), a smaller cylinder might be preferred, even if it requires more frequent refilling.

-Weight vs. Capacity: Striking a balance between weight and capacity is essential. While a larger cylinder offers more gas, it will also be heavier.

The Cost Conundrum: A Balancing Act

There’s no denying the benefits of carbon fiber air cylinders. However, their biggest weakness lies in cost. Carbon fiber cylinders typically have a higher upfront cost compared to steel options. This can be a significant factor for budget-conscious users.

The Future of Compressed Air Storage: Lighter and Brighter

The evolution of carbon fiber technology is shaping the future of compressed air storage. Here are some exciting possibilities:

-Advanced Composite Materials: Research and development efforts might lead to even stronger and lighter composite materials for cylinder construction.

-Multi-Gas Compatibility: Future advancements might allow for carbon fiber cylinders to safely store a wider range of compressed gases.

-Smart Cylinder Technology: Integration of sensors and communication capabilities could lead to “smart” carbon fiber cylinders that monitor pressure levels and gas remaining.

The Final Verdict: A Choice for the Weight-Conscious User

Carbon fiber air cylinders are a game-changer for applications where portability and weight reduction are crucial. Their advantages in terms of durability, corrosion resistance, and potential for higher pressure ratings make them a compelling choice. While the higher initial cost might be a concern, the long-term benefits need to be factored in. Ultimately, the choice between carbon fiber and steel depends on individual needs and priorities. For weight-conscious users who prioritize maneuverability and comfort, carbon fiber offers a significant advantage, paving the way for a lighter and more efficient future of compressed air storage.

Post time: May-14-2024