In the last decade, gas storage technology has undergone a significant transformation with the introduction of Carbon Fiber Composite Cylinders. These cylinders, engineered for high-pressure compressed air storage, employ an advanced combination of materials including an aluminum liner, carbon fiber winding, and an outer layer of glass fiber. This article explores the intricate roles of these components, highlighting their collective contribution to enhancing safety, portability, stability, durability, and reliability compared to traditional steel cylinders.

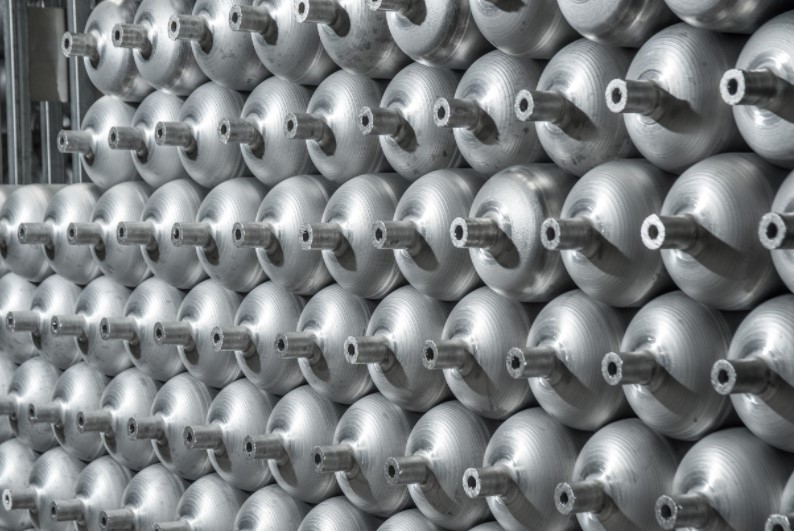

Aluminum Liner: The Lightweight Core

At the heart of the composite cylinder lies the aluminum liner. This component acts as the primary container for the compressed air, ensuring the structural integrity of the cylinder. Aluminum is chosen for its exceptional strength-to-weight ratio, which significantly reduces the overall weight of the cylinder while maintaining robustness. This lightweight nature of aluminum facilitates better portability, a crucial feature for applications where mobility is paramount, such as firefighting, emergency rescue operations, and medical applications. Additionally, aluminum is resistant to corrosion, which further extends the lifespan of the liner and, consequently, the cylinder itself.

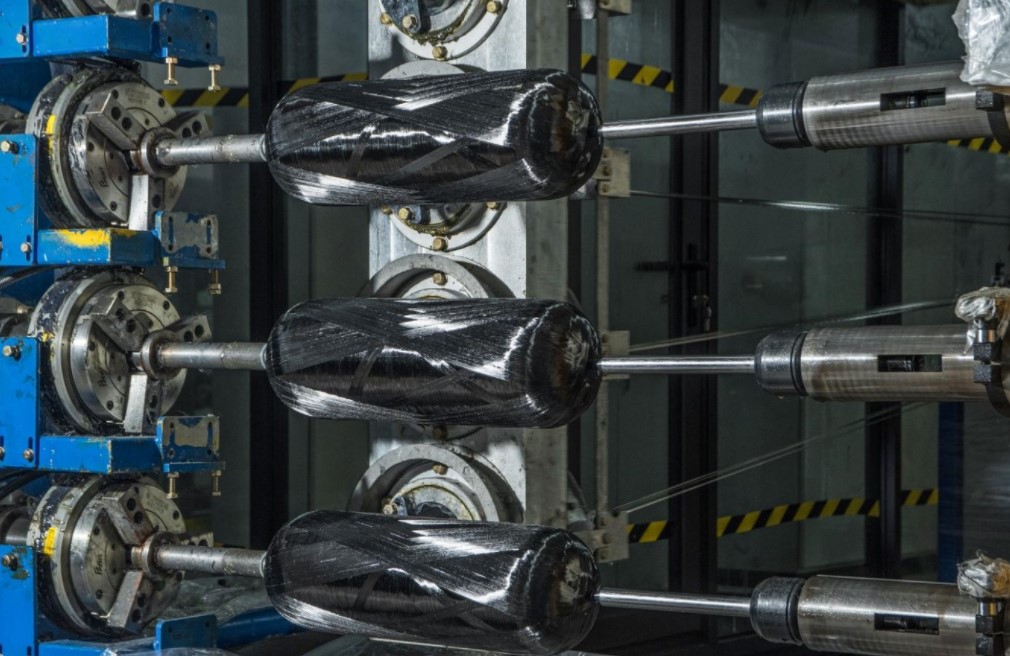

Carbon Fiber Winding: The Strength Enhancer

Encasing the aluminum liner is the carbon fiber winding, a critical element that imparts unmatched strength to the composite cylinder. Carbon fiber is renowned for its high tensile strength and low density, making it an ideal material for applications that demand both durability and lightweight characteristics. The carbon fiber winding process involves wrapping the fibers around the aluminum liner in a seamless manner, which enhances the structural uniformity of the cylinder. This seamless winding minimizes weak points and significantly boosts the cylinder’s ability to withstand high pressure and external impacts. The use of carbon fiber not only increases the cylinder’s strength but also contributes to its overall stability and reliability under various operational conditions.

Outer Layer of Glass Fiber: The Protective Shield

The outermost layer of the composite cylinder is made of glass fiber, which serves as a protective shield for the internal components. Glass fiber is chosen for its excellent resistance to abrasion, impact, and environmental factors such as UV radiation and moisture. This layer adds an extra level of durability, safeguarding the cylinder from external wear and tear. The synergy between glass fiber and carbon fiber results in a robust outer shell that enhances the cylinder’s longevity and reliability, ensuring it remains operational over extended periods and under harsh conditions.

Performance Comparison with Traditional Steel Cylinders

Safety: One of the primary advantages of carbon fiber composite cylinders over traditional steel cylinders is their superior safety profile. The combination of aluminum, carbon fiber, and glass fiber results in a cylinder that can withstand higher pressures without risk of rupture. The materials used in composite cylinders are less prone to catastrophic failure modes, such as explosions, which are a risk with steel cylinders under certain conditions.

Portability: The lightweight design of carbon fiber composite cylinders is a significant benefit over their steel counterparts. Steel cylinders are heavy and cumbersome, making them difficult to transport, especially in scenarios that require quick movement and agility. In contrast, composite cylinders, due to the lightweight nature of aluminum and carbon fiber, are easier to handle and move. This portability is particularly advantageous in fields like firefighting and medical emergencies where equipment needs to be rapidly deployed.

Stability: The structural stability of composite cylinders is another area where they excel. The integration of aluminum, carbon fiber, and glass fiber ensures that the cylinder maintains its shape and integrity even under high pressure and external impacts. The seamless winding of carbon fiber around the aluminum liner minimizes deformation and potential weak points, ensuring the cylinder remains stable and reliable in various environments.

Durability: The durability of carbon fiber composite cylinders surpasses that of traditional steel cylinders. The outer layer of glass fiber provides additional protection against environmental factors and physical damage, such as scratches and impacts. This durability ensures that composite cylinders have a longer operational life, reducing the need for frequent replacements and maintenance.

Reliability: Carbon fiber composite cylinders are engineered with meticulous precision and undergo stringent quality control processes during production. This attention to detail ensures that each cylinder meets high standards of reliability and performance. The combination of advanced materials and precise manufacturing techniques results in a product that users can trust to perform consistently under demanding conditions.

Advantages of Carbon Fiber Cylinders in Specific Applications

The use of carbon fiber composite cylinders offers distinct advantages across various applications:

Firefighting: Firefighters require equipment that is both reliable and easy to maneuver. The lightweight nature of composite cylinders allows firefighters to carry more air without being weighed down, enhancing their mobility and effectiveness in rescue operations.

Medical Use: In medical emergencies, the ability to quickly transport and deploy life-saving equipment is crucial. Composite cylinders, being lighter and more portable, ensure that medical personnel can respond swiftly and efficiently.

Industrial Applications: In industries where high-pressure gas storage is necessary, the durability and stability of composite cylinders reduce the risk of accidents and equipment failure, ensuring a safer working environment.

Conclusion

The advent of Carbon Fiber Composite Cylinders represents a revolutionary shift in gas storage technology. The sophisticated combination of an aluminum liner, carbon fiber winding, and glass fiber outer layer provides unmatched advantages in safety, portability, stability, durability, and reliability. Compared to traditional steel cylinders, composite cylinders offer a superior solution for high-pressure compressed air storage, making them indispensable in various critical applications. As technology continues to evolve, the adoption of carbon fiber composite cylinders is poised to become the standard, driving advancements in safety and efficiency across multiple industries.

Post time: Jul-11-2024