In the realm of aerospace and aviation, the pursuit of efficiency, safety, and performance is relentless. One of the key players in this quest is the carbon fiber cylinder, a marvel of modern engineering that has revolutionized fuel and air storage in aircraft. In this article, we delve into the role of these lightweight yet high-strength cylinders and how they are shaping the future of flying.

The Emergence of Carbon Fiber Technology in Aerospace

Carbon fiber, known for its strength-to-weight ratio superior to that of traditional materials like steel or aluminum, has become a staple in aircraft manufacturing. Its introduction into cylinder technology marks a significant leap forward. These cylinders, made from carbon fiber-reinforced polymers, offer a combination of durability and lightness that is crucial in aviation.

Weight Reduction and Fuel Efficiency

One of the primary benefits of carbon fiber cylinders in aerospace is the significant reduction in weight. Every kilogram saved contributes to lower fuel consumption and increased range or payload capacity. This weight efficiency is vital for both commercial airlines seeking to reduce operating costs and military aircraft where performance and payload are critical.

Safety and Durability

Despite their lightweight nature, carbon fiber cylinders are remarkably strong and resistant to corrosion. This durability ensures that they can withstand the high pressures and extreme conditions encountered in aviation. Furthermore, carbon fiber does not fatigue over time like metal, making these cylinders safer and more reliable over their lifespan.

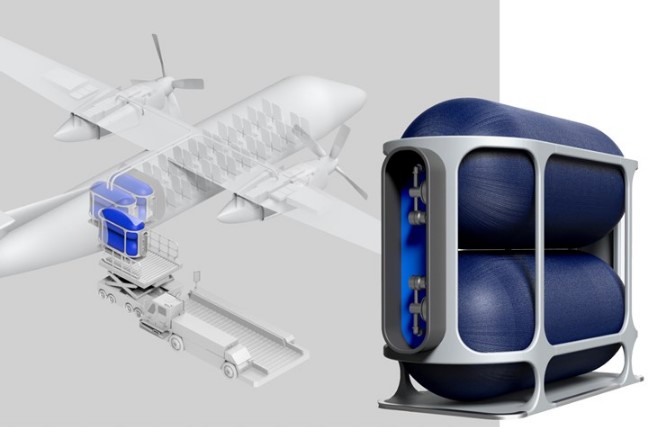

Applications in Fuel and Air Storage

In the aerospace sector, carbon fiber cylinders are utilized in various capacities. They serve as storage vessels for compressed gases like oxygen for crew and passengers in commercial airliners. In military aircraft, these cylinders are used for emergency ejection systems and to store gases for operating various aircraft systems.

Impact on Aircraft Design

The use of carbon fiber cylinders has also influenced aircraft design. With lighter cylinders, designers can rethink the allocation of weight and space within the aircraft, leading to more efficient designs and the possibility of incorporating additional features or systems.

Environmental Considerations

Reduced fuel consumption directly translates into lower carbon emissions, aligning with the aviation industry’s goals to minimize its environmental footprint. The lightweight nature of these cylinders plays a crucial role in achieving more eco-friendly flights.

Future Developments and Challenges

The potential for carbon fiber in aerospace is vast, with research ongoing to enhance its properties further. The challenges lie in reducing manufacturing costs and ensuring consistent quality in mass production. Additionally, as carbon fiber becomes more prevalent, the industry must address recycling and end-of-life disposal issues.

Carbon fiber cylinders have become a vital component in the aerospace and aviation industries, driving advancements in efficiency, safety, and design. As technology evolves, we can expect these materials to play an increasingly significant role in the future of air travel. The journey of carbon fiber cylinders from a novel idea to a crucial aerospace component is a testament to the ever-evolving nature of aviation technology, soaring to new heights with each innovation.

So some one could have question whether does the weight of cylinders, given their relatively small size compared to the overall aircraft, significantly impact the efficiency and performance of the aircraft? Let’s break it down to understand the importance of weight management in aviation and how even small reductions can have a meaningful impact

1. The Cumulative Effect of Weight Reduction:

While it’s true that individually, items like carbon fiber cylinders might seem insignificant in weight compared to the total mass of an aircraft, the cumulative effect of multiple lightweight components is substantial. In aviation, every kilogram saved accumulates over time to yield significant fuel savings and reduced carbon emissions. It’s not just about the weight of a single component but the overall reduction across the aircraft.

2. Fuel Efficiency:

Fuel efficiency is one of the most critical factors in aviation, both from a cost and environmental perspective. The heavier the aircraft, the more fuel it burns. Even small weight savings can lead to reduced fuel consumption, which is crucial for long-haul flights where fuel costs can represent a significant portion of operating expenses.

3. Payload and Range:

Reducing the weight of components like cylinders allows for an increased payload or extended range. This means aircraft can carry more passengers or cargo without sacrificing performance. In some cases, weight savings can enable aircraft to reach destinations without the need for refueling stops, making flights more efficient and convenient.

4. Design Flexibility:

Lightweight components like carbon fiber cylinders provide designers with more flexibility. By reducing the weight in one area, designers can redistribute weight for other essential features or systems, improving the overall functionality and performance of the aircraft.

5. Safety and Performance:

In high-performance aircraft, such as military jets, every kilogram saved can enhance agility, speed, and operational capabilities. Similarly, in commercial aviation, weight savings contribute to safety by reducing the strain on critical components.

6. Lifecycle Costs:

Lighter aircraft generally put less stress on their components, potentially leading to lower maintenance costs and longer lifespans for parts. Over the aircraft’s lifetime, these savings can be substantial.

Conclusion:

In conclusion, while each individual cylinder may not weigh much in the grand scheme of an aircraft, the collective weight savings from using lighter materials like carbon fiber have a significant impact. In an industry where efficiency, safety, and performance are paramount, and where operating margins can be thin, every small improvement counts. It’s a case where the sum of the parts makes a greater whole, and each weight reduction, no matter how small, contributes to the aircraft’s overall performance and efficiency.

Post time: Jan-30-2024