The advancement of materials and design methodologies has revolutionized the realm of pressure vessels, leading to increased efficiency and reliability. At the heart of this transformation lies carbon fiber, a material renowned for its exceptional strength-to-weight ratio. This article delves into the revolutionary advancements in the structural analysis and design optimization of cylinders, focusing on how carbon fiber has dramatically altered the landscape.

Unmatched Strength of Carbon Fiber

Carbon fiber stands out due to its remarkable strength and durability, making it an ideal choice for constructing pressure vessels. The material’s unique combination of high tensile strength and low weight ensures structural integrity while enhancing portability and performance. These properties make carbon fiber a preferred material in industries requiring robust yet lightweight solutions.

Advanced Structural Analysis

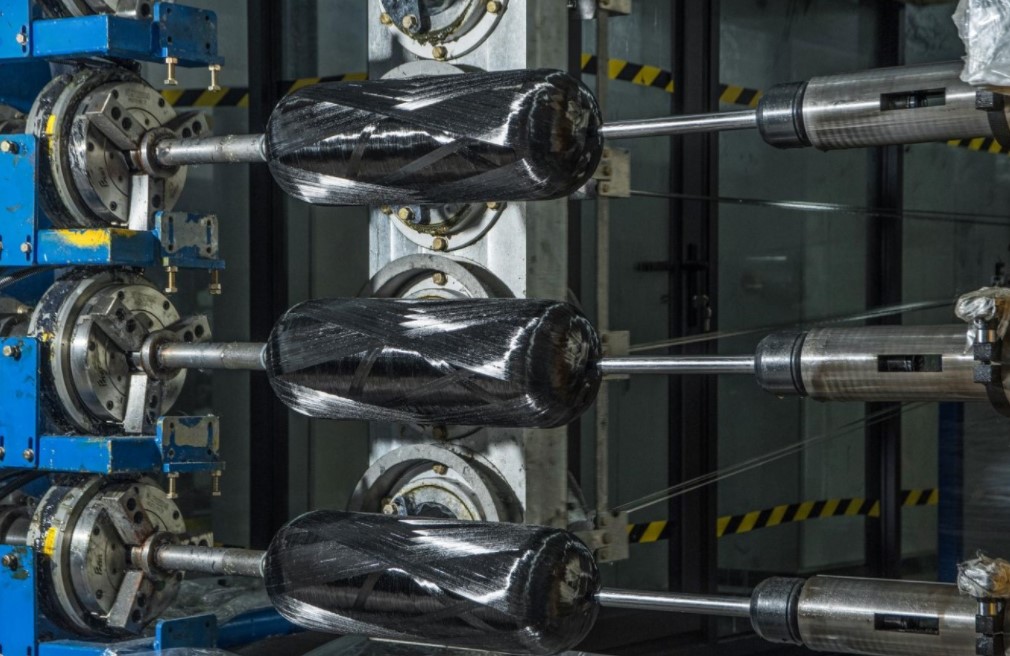

The structural analysis of carbon fiber cylinders involves a thorough examination of their load-bearing capabilities, stress distribution, and overall stability. A critical tool in this process is Finite Element Analysis (FEA), which allows engineers to simulate various conditions and assess the cylinder’s response to external forces.

One of the significant advantages revealed through structural analysis is carbon fiber’s ability to withstand high levels of stress without a corresponding increase in weight. This characteristic is vital for industries where lightweight yet strong cylinders are essential, such as aerospace, automotive, and recreational applications like paintball and airgun power storage.

Optimizing Design for Performance

Design optimization plays a crucial role in leveraging the full potential of carbon fiber cylinders. Engineers focus on refining the geometry, layering, and orientation of the carbon fiber composite to achieve the best balance between strength, weight, and durability. The objective is to maximize performance while minimizing material use, contributing to economic and environmental sustainability.

Enhanced computer-aided design tools enable engineers to experiment with various configurations, allowing for precise adjustments that improve the overall performance of the cylinders. This iterative process ensures that the final product meets the stringent requirements of modern applications.

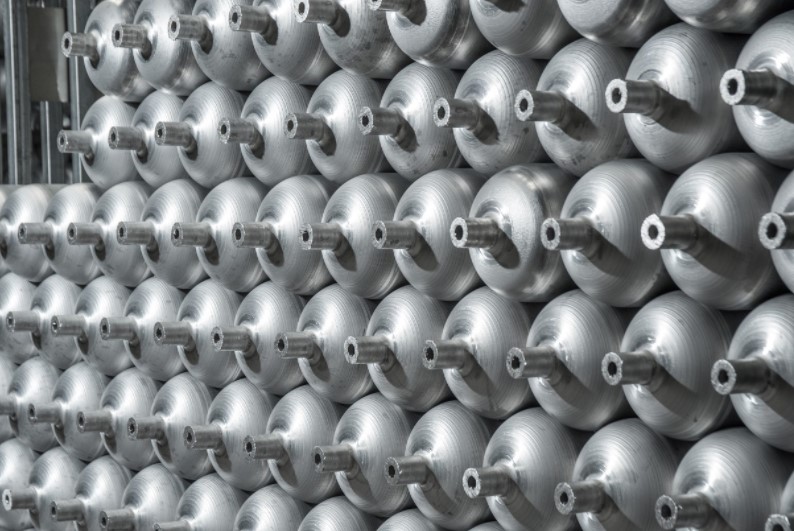

Superior Durability and Longevity

One of the most impressive features of carbon fiber cylinders is their extended operational lifespan. Through meticulous design optimization and comprehensive structural analysis, engineers can create cylinders that withstand the test of time, providing long-lasting reliability. This durability is particularly crucial in critical sectors such as firefighting, where the longevity of equipment can be a matter of life and death.

Real-world Applications and Versatility

The application of carbon fiber cylinders spans a wide range of industries. Their lightweight yet sturdy nature makes them indispensable in scenarios where every ounce matters. Some notable applications include:

1.Aerospace: The aerospace industry benefits greatly from carbon fiber cylinders due to their lightweight nature, which helps reduce overall aircraft weight and improve fuel efficiency.

2.Automotive: In the automotive sector, carbon fiber cylinders are used in high-performance vehicles to enhance performance while maintaining safety standards.

3.Recreational Activities: For recreational applications such as paintball and airguns, carbon fiber cylinders offer a perfect balance of portability and strength, ensuring consistent performance during use.

4.Firefighting: Firefighters rely on carbon fiber cylinders for their breathing apparatus. The cylinders’ lightweight and durable properties make them ideal for use in high-pressure situations where equipment reliability is paramount.

Conclusion: Shaping the Future of Pressure Vessel Technology

In the dynamic field of pressure vessel technology, the structural analysis and design optimization of carbon fiber cylinders represent a significant leap forward. The integration of cutting-edge materials with innovative design methodologies has led to the development of cylinders that are not only stronger and lighter but also more durable and versatile.

As industries continue to prioritize performance, efficiency, and safety, carbon fiber cylinders stand out as a beacon of progress. Their unparalleled strength-to-weight ratio, combined with advanced design techniques, ensures they will play a pivotal role in the future of pressure vessel technology. These advancements underscore the ongoing evolution in engineering, highlighting the importance of innovation in meeting the demands of modern applications.

Post time: Jul-22-2024