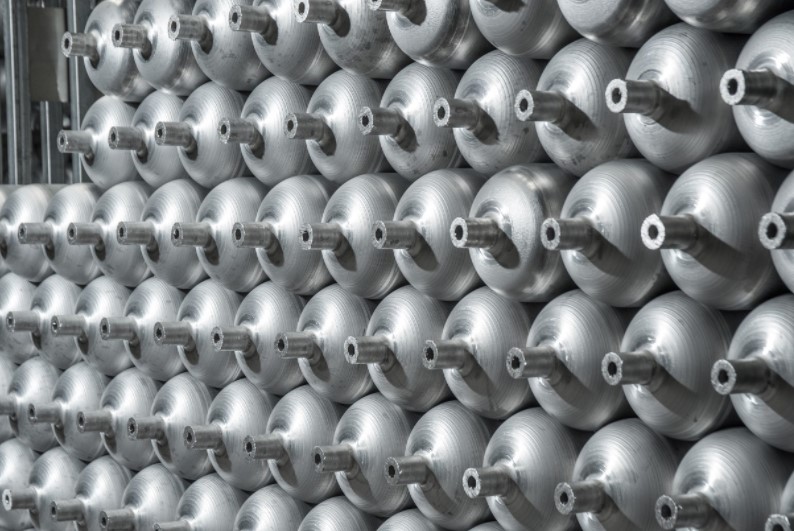

Self-Contained Breathing Apparatus (SCBA) cylinders are critical for providing breathable air to firefighters, rescue workers, and other personnel working in hazardous environments. Knowing how long an SCBA cylinder will last during use is vital for planning operations and ensuring safety. The working duration of a cylinder depends on its volume, pressure, and the breathing rate of the user. This article will walk you through how to calculate the capacity of an SCBA cylinder, using a simple formula, with special attention to carbon fiber composite cylinders, which are widely used due to their lightweight and strength.

SCBA Cylinder Basics: Volume and Pressure

SCBA cylinders store compressed air at high pressure, typically measured in bars or pounds per square inch (PSI). The volume of air inside the cylinder is usually expressed in liters. The two main factors that determine how much air is available are:

- Cylinder Volume: This is the internal size of the cylinder, often expressed in liters (e.g., 6.8-liter or 9-liter).

- Cylinder Pressure: The pressure at which the air is stored, typically between 200 and 300 bar for SCBA cylinders.

Carbon fiber composite cylinders are popular in SCBA systems because they offer a higher pressure capacity (up to 300 bar) while being much lighter than traditional steel or aluminum cylinders. This makes them ideal for situations where users need to move quickly or for extended periods.

The Formula for Calculating SCBA Duration

The working duration of an SCBA cylinder can be calculated using the following formula:

- The “40″ in the formula represents the average breathing rate of a person under moderate work conditions. This rate can vary depending on how hard the user is working, but 40 liters per minute (L/min) is a standard figure.

- The “-10″ at the end of the formula is a safety margin, ensuring the user has time to exit the hazardous area before the air runs out completely.

Example Calculation:

Let’s calculate the working duration for a 6.8-liter carbon fiber SCBA cylinder, pressurized to 300 bar.

In this example, the SCBA cylinder would provide approximately 35 minutes of breathable air before needing to be replaced or refilled. This calculation assumes moderate physical activity, and actual usage time may vary if the user is exerting themselves more or less.

Factors Affecting SCBA Cylinder Duration

While the formula provides a basic estimate, several factors can influence

the actual duration of an SCBA cylinder in use. Understanding these variables is key to ensuring safe operations.

1. Breathing Rate

The formula assumes an average breat

hing rate of 40 L/min, which corresponds to moderate activity. In reality, the breathing rate can fluctuate depending on the user’s workload:

- Low Activity: If the user is at rest or performing light work, the breathing rate could be lower, around 20-30 L/min, which would extend the cylinder’s duration.

- High Activity: During heavy physical activity, such as fighting fires or rescuing people, breathing rates can increase to 50-60 L/min or more, reducing the cylinder’s duration.

2. Cylinder Pressure

Higher pressure cylinders provide more air for the same volume. Carbon fiber cylinders typically operate at pressures of up to 300 bar, compared to steel or aluminum cylinders, which may be limited to 200 bar. The higher pressure allows carbon fiber cylinders to hold more air in a smaller, lighter package, extending the working duration.

3. Safety Margin

The safety margin built into the formula (-10 minutes) ensures that the

user does not run out of air while still in a hazardous environment. It’s important to respect this buffer when calculating the working time and planning air usage, especially in situations where the exit route may take several minutes to traverse.

T

he Role of Carbon Fiber Composite Cylinders

Carbon fiber composite cylinders have become the preferred choice for SCBA systems due to their lightweight design and ability to hold higher pressures. Compared to steel and aluminum cylinders, carbon fiber cylinders offer several benefits:

- Weight: Carbon fiber cylinders are significantly lighter than steel, making them easier to carry and reducing fatigue for the user during extended operations.

- Higher Pressure: They can be filled to pressures up to 300 bar, providing more air without increasing the cylinder’s size.

- Durability: Carbon fiber composites are extremely strong, able to withstand high pressures while also being resistant to impact and environmental factors.

The lightweight design is particularly important for rescue workers who need to remain mobile while carrying other equipment, such as firefighting tools or medical gear. Despite their advantages, carbon fiber cylinders do come with some additional maintenance requirements, such as regular hydrostatic testing to ensure they remain safe under pressure.

Hydrostatic Testing and SCBA Cylinder Maintenance

To maintain the reliability of SCBA cylinders, including carbon fiber models, regular maintenance is essential. This includes:

- Visual Inspections: Check for damage, such as cracks or dents, before each use.

- Hydrostatic Testing: Carbon fiber SCBA cylinders typically require hydrostatic testing every five years to ensure they can handle the high pressures involved. This test checks for any expansion in the cylinder that might indicate weakening of the material.

- Replacement: Even with proper maintenance, carbon fiber SCBA cylinders have a finite lifespan, usually around 15 years, after which they must be replaced.

Conclusion

Knowing how to calculate the capacity and working duration of SCBA cylinders is

crucial for anyone who relies on these devices in hazardous environments. Using the formula (Volume × Pressure) / 40 – 10, you can estimate the time available in any given cylinder, keeping in mind that breathing rates, pressure, and safety margins all play a role in the final duration.

Carbon fiber composite cylinders, with their lightweight design and ability to hold high pressures, are a popular choice for SCBA systems. They offer longer working durations and improved mobility compared to steel or aluminum cylinders. However, regular maintenance, including visual inspections and hydrostatic testing, is critical to ensure these cylinders remain safe and effective throughout their service life.

Understanding these aspects of SCBA cylinder capacity will help ensure safe and effective use in challenging environments, where every minute of breathable air can make a difference.

Post time: Sep-14-2024