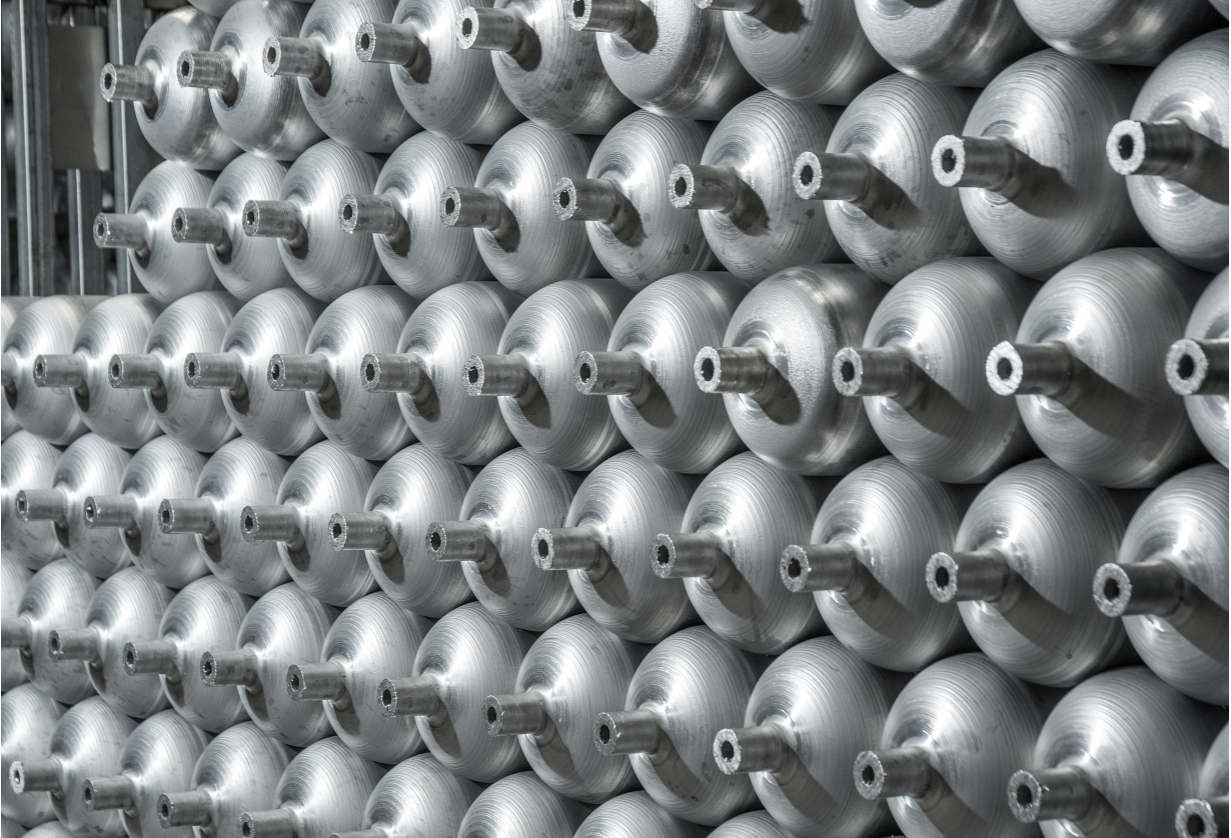

The production process of an aluminum liner for Type 3 carbon fiber cylinders is critical to ensuring the quality and safety of the final product. Here are the essential steps and points to consider when manufacturing and inspecting the liner:

Production Process:

1.Aluminium Selection: The process begins with selecting high-quality, corrosion-resistant aluminium alloy sheets. These sheets should meet specific material standards to ensure durability and safety.

2.Shaping and Forming the Liner: Aluminum alloy sheets are then formed into a cylinder shape, matching the internal dimensions of the carbon fiber composite cylinder. The liner should be precisely manufactured to fit finished product size.

3.Heat Treatment: The liner should be treated to enhance corrosion resistance and improve its functionality.

Quality Control and Inspection:

1.Dimensional Accuracy: The liner’s dimensions must align precisely with the interior dimensions of the composite shell. Any deviations can affect the fit and performance of the cylinder.

2.Surface Finish: The interior surface of the liner should be smooth and free from imperfections that could impact gas flow or promote corrosion. Surface treatments, if used, must be consistent and well-applied.

3.Gas Leak Testing: The liner should undergo a gas leak test to ensure that there are no leaks or weak points in the welds or seams. This test helps confirm the liner’s gas-tight integrity.

4.Material Inspection: Ensure that the aluminium material used meets the required standards for strength, corrosion resistance, and compatibility with the stored gases.

5.Non-Destructive Testing: Techniques such as ultrasonic testing and X-ray inspection can be employed to identify hidden defects in the liner, such as internal cracks or inclusions.

6.Quality Documentation: Maintain detailed records of the manufacturing process, inspections, and test results. This documentation is essential for traceability and quality control.

Adherence to Standards: Ensure that the liner manufacturing process complies with relevant industry standards and regulations, such as those set by organizations like ISO, DOT (Department of Transportation), and EN (European Norms).

By following these steps and conducting thorough inspections, manufacturers can produce aluminium liners that meet the stringent quality and safety requirements for Type 3 carbon fiber cylinders used in various applications, including firefighting, SCBA (Self-Contained Breathing Apparatus), and more.

Post time: Oct-26-2023