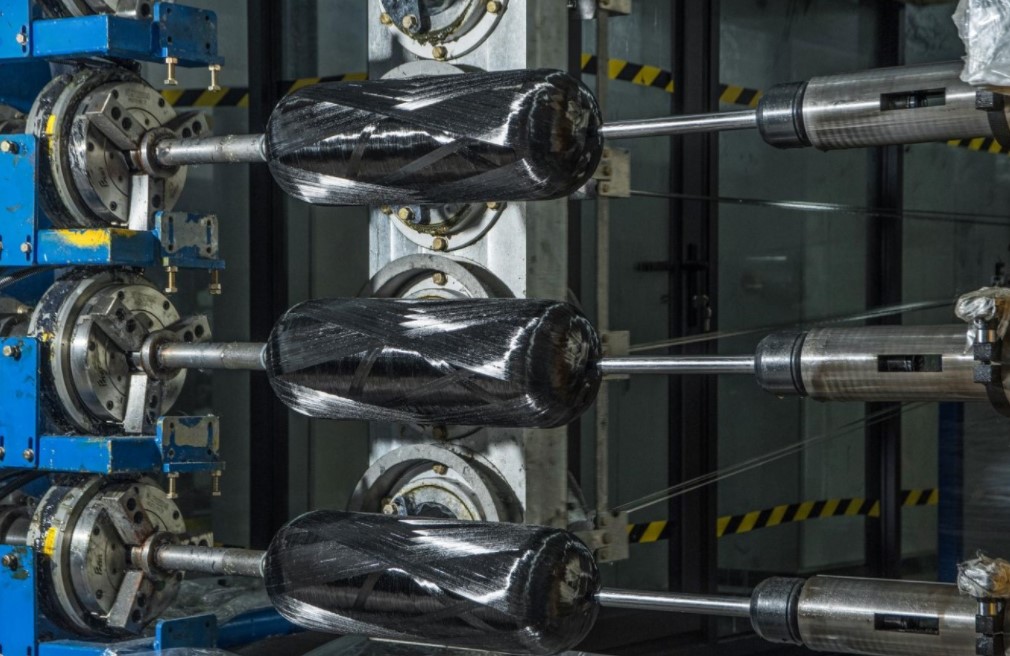

As the world transitions toward sustainable transportation, new energy vehicles (NEVs), including hydrogen fuel cell and hybrid electric cars, are gaining traction. One crucial component enabling the advancement of NEVs is the carbon fiber cylinder. These cylinders are essential for storing compressed hydrogen, a clean fuel source for hydrogen fuel cell vehicles. Their lightweight, high-strength design makes them a perfect fit for the demanding requirements of the automotive industry.

The Growing Role of Hydrogen in NEVs

Hydrogen-powered vehicles are considered a promising solution for reducing greenhouse gas emissions and dependency on fossil fuels. In these cars, hydrogen is stored in compressed form and used in fuel cells to generate electricity, which powers the vehicle’s motor. To make this process safe, efficient, and viable for everyday use, high-performance storage solutions like carbon fiber cylinders are essential.

Advantages of Carbon Fiber Cylinders for NEVs

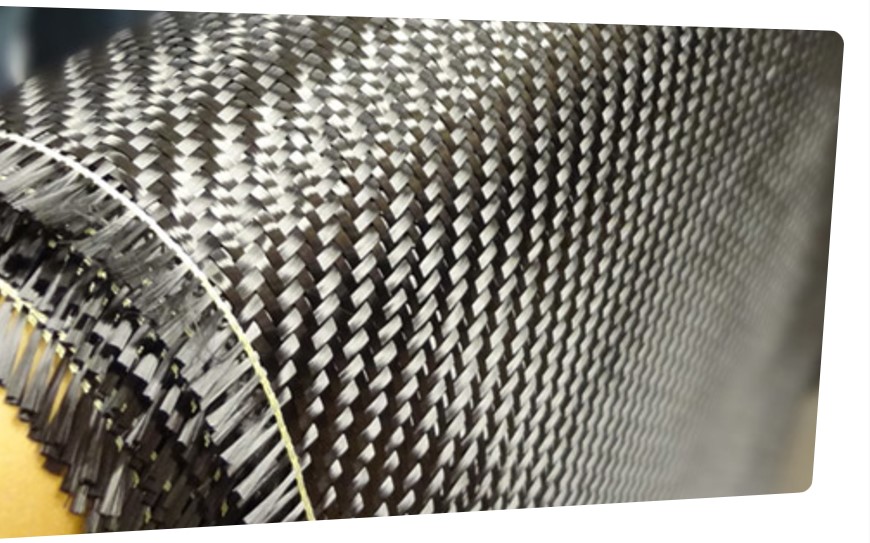

1. Lightweight Construction

Carbon fiber composite cylinders are significantly lighter than traditional steel or aluminum tanks. This weight reduction is critical in vehicles, where every kilogram saved contributes to improved energy efficiency, longer driving range, and better overall performance.

2. High Strength and Durability

Despite being lightweight, carbon fiber cylinders are incredibly strong. They are designed to withstand high pressures, typically up to 700 bar (10,000 psi) or more, which is necessary for storing hydrogen in a compressed state. This strength ensures safety and reliability during vehicle operation.

3. Corrosion Resistance

Traditional metal tanks are susceptible to rust and corrosion over time, particularly when exposed to environmental factors like humidity. Carbon fiber cylinders are inherently resistant to corrosion, making them ideal for long-term use in varying conditions.

4. Compact Design

The ability to store compressed gas at high pressures allows carbon fiber cylinders to hold more hydrogen in a smaller space. This compact design helps maximize storage capacity without taking up excessive room in the vehicle, preserving space for passengers and cargo.

Applications in Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles rely on high-pressure storage systems to keep hydrogen gas available for on-demand use. Carbon fiber cylinders are used to:

- Store Hydrogen Safely

Hydrogen is a highly flammable gas, so safe storage is paramount. Carbon fiber cylinders are designed to meet rigorous safety standards, ensuring they can handle high pressures without risk of rupture or leakage. - Enable Longer Driving Ranges

The lightweight design of these cylinders allows vehicles to store more hydrogen without adding significant weight, resulting in extended driving ranges compared to traditional fuel cell tanks. - Improve Vehicle Efficiency

By reducing the overall weight of the storage system, carbon fiber cylinders contribute to the efficiency of hydrogen-powered vehicles, allowing them to achieve better mileage with less energy consumption.

Challenges and Innovations

While carbon fiber cylinders offer numerous advantages, there are challenges to consider:

1. Cost

Manufacturing carbon fiber composite materials is more expensive than producing traditional steel or aluminum tanks. However, ongoing advancements in production techniques are gradually reducing costs.

2. Recycling and Sustainability

Although carbon fiber is durable, recycling composite materials poses technical challenges. Researchers are working on innovative solutions to make carbon fiber cylinders more sustainable at the end of their lifecycle.

3. Integration with Vehicle Design

Efficiently integrating carbon fiber cylinders into NEV designs requires careful planning to optimize space, weight distribution, and performance.

Beyond Hydrogen Fuel Cell Vehicles

While hydrogen storage is the primary use case for carbon fiber cylinders in new energy cars, there are other potential applications:

- Compressed Natural Gas (CNG) Vehicles

Some vehicles use CNG as an alternative fuel. Carbon fiber cylinders can store compressed natural gas in a lightweight and efficient manner, similar to hydrogen. - Emergency Backup Systems

In hybrid vehicles, carbon fiber cylinders can be used to store compressed gas for auxiliary power systems or emergency backup.

Environmental and Economic Benefits

Using carbon fiber cylinders in NEVs aligns with the global push for sustainability:

- Reduced Emissions

By enabling hydrogen-powered vehicles, these cylinders help reduce greenhouse gas emissions and promote cleaner air. - Improved Fuel Efficiency

The lightweight nature of carbon fiber cylinders reduces overall vehicle weight, leading to better fuel efficiency and lower energy consumption. - Support for Renewable Energy

Hydrogen can be produced from renewable sources like solar or wind energy. The use of carbon fiber cylinders facilitates the storage and use of this green hydrogen in vehicles.

Future Prospects

As the adoption of new energy vehicles grows, so does the demand for innovative storage solutions. Carbon fiber cylinders are poised to play a central role in this evolution. Advances in material science and production methods will likely make these cylinders even more efficient, cost-effective, and sustainable in the coming years.

Conclusion

Carbon fiber cylinders are transforming the way new energy cars operate. Their lightweight, durable, and efficient design makes them an essential component for hydrogen fuel cell vehicles and other alternative energy systems. By enabling longer driving ranges, improved safety, and better overall vehicle performance, these cylinders are helping to drive the future of sustainable transportation.

As the automotive industry continues its shift toward greener technologies, carbon fiber cylinders will remain a key innovation in achieving cleaner, more efficient mobility.

Post time: Nov-25-2024