When it comes to materials used in high-performance applications, such as SCBA (Self-Contained Breathing Apparatus) cylinders, carbon fiber and steel are often compared for their durability and weight. Both materials have distinct properties that make them suitable for different uses. Understanding these differences can help in choosing the right material for specific needs. This article will explore how carbon fiber compares to steel in terms of durability and weight, focusing particularly on the use of carbon fiber composite cylinders.

Durability

1. Carbon Fiber Durability

Carbon fiber is known for its exceptional durability, especially in terms of tensile strength. Tensile strength refers to a material’s ability to resist forces that attempt to stretch or pull it apart. Carbon fiber boasts high tensile strength, which means it can withstand substantial loads without stretching or breaking. This property makes it ideal for applications where strength and reliability are critical.

- Impact Resistance: Carbon fiber composites are designed to absorb and distribute impact forces effectively. This resistance to impact damage makes carbon fiber cylinders robust, even in challenging conditions. They are less likely to suffer from dents or deformations compared to steel cylinders, which can compromise their structural integrity.

- Corrosion Resistance: One of the significant advantages of carbon fiber is its resistance to corrosion. Unlike steel, which can rust and degrade when exposed to moisture and chemicals, carbon fiber does not corrode. This property is particularly valuable in environments where exposure to water or chemicals is common.

2. Steel Durability

Steel is also known for its strength and durability. However, it differs from carbon fiber in several ways:

- Tensile Strength: While steel is strong, it generally does not match the tensile strength of carbon fiber. Steel can handle significant stress, but it is more prone to stretching and deforming under extreme loads.

- Impact Resistance: Steel is relatively resistant to impact forces but can be dented or deformed when subjected to high impacts. Unlike carbon fiber, which absorbs impacts, steel tends to absorb the energy and can sustain visible damage.

- Corrosion Resistance: Steel is susceptible to corrosion, especially if it is not properly coated or treated. Corrosion can weaken steel over time, leading to potential safety concerns. Regular maintenance and protective coatings are often required to extend the lifespan of steel components.

Weight

1. Carbon Fiber Weight

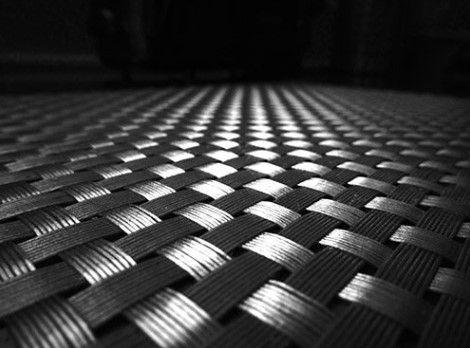

One of the most significant advantages of carbon fiber is its lightweight nature. Carbon fiber composites are made from extremely thin fibers woven together and embedded in a resin matrix. This construction provides high strength without adding much weight.

- Lightweight Advantage: Carbon fiber is much lighter than steel. For example, a carbon fiber SCBA cylinder can weigh up to 60% less than a traditional steel cylinder of the same size. This reduction in weight is crucial in applications where reducing the load is essential for efficiency and ease of use.

- Design Flexibility: The lightweight nature of carbon fiber allows for greater design flexibility. Engineers can design more compact and efficient cylinders without compromising strength. This flexibility leads to improved performance and ease of handling.

2. Steel Weight

Steel is significantly heavier compared to carbon fiber. This weight can be a disadvantage in applications where reducing load is important.

- Heavier Components: Steel cylinders, being heavier, can be more cumbersome to handle and transport. For example, a steel SCBA cylinder will be bulkier and more tiring to carry, which can be a concern in high-intensity situations like firefighting.

- Less Design Flexibility: The additional weight of steel limits design options. To achieve similar strength to carbon fiber, steel components need to be thicker, which adds to the overall weight and bulkiness of the product.

Applications of Carbon Fiber and Steel Cylinders

- SCBA Systems: Carbon fiber cylinders are commonly used in SCBA systems due to their lightweight and durable properties. Firefighters and rescue workers benefit from the reduced weight, which enhances mobility and reduces fatigue during operations.

- Aerospace and Sports: Carbon fiber’s strength-to-weight ratio makes it ideal for use in aerospace components and high-performance sports equipment, where reducing weight is critical without sacrificing strength.

2. Steel Cylinders

- Industrial Uses: Steel cylinders are often used in industrial applications where high strength is needed, and the weight is less of a concern. They are also used in situations where cost considerations make them a viable option despite their heavier weight.

- Traditional Applications: Steel continues to be used in many traditional applications due to its robustness and lower initial cost, although it requires more maintenance to prevent corrosion.

Conclusion

In summary, carbon fiber and steel offer different advantages when it comes to durability and weight. Carbon fiber outperforms steel in terms of tensile strength, providing superior strength while being significantly lighter. This makes carbon fiber composite cylinders ideal for applications requiring high performance and reduced weight, such as SCBA systems. On the other hand, steel offers robust strength but is heavier and more prone to corrosion. Understanding these differences helps in choosing the right material based on specific needs and application requirements.

Post time: Sep-03-2024