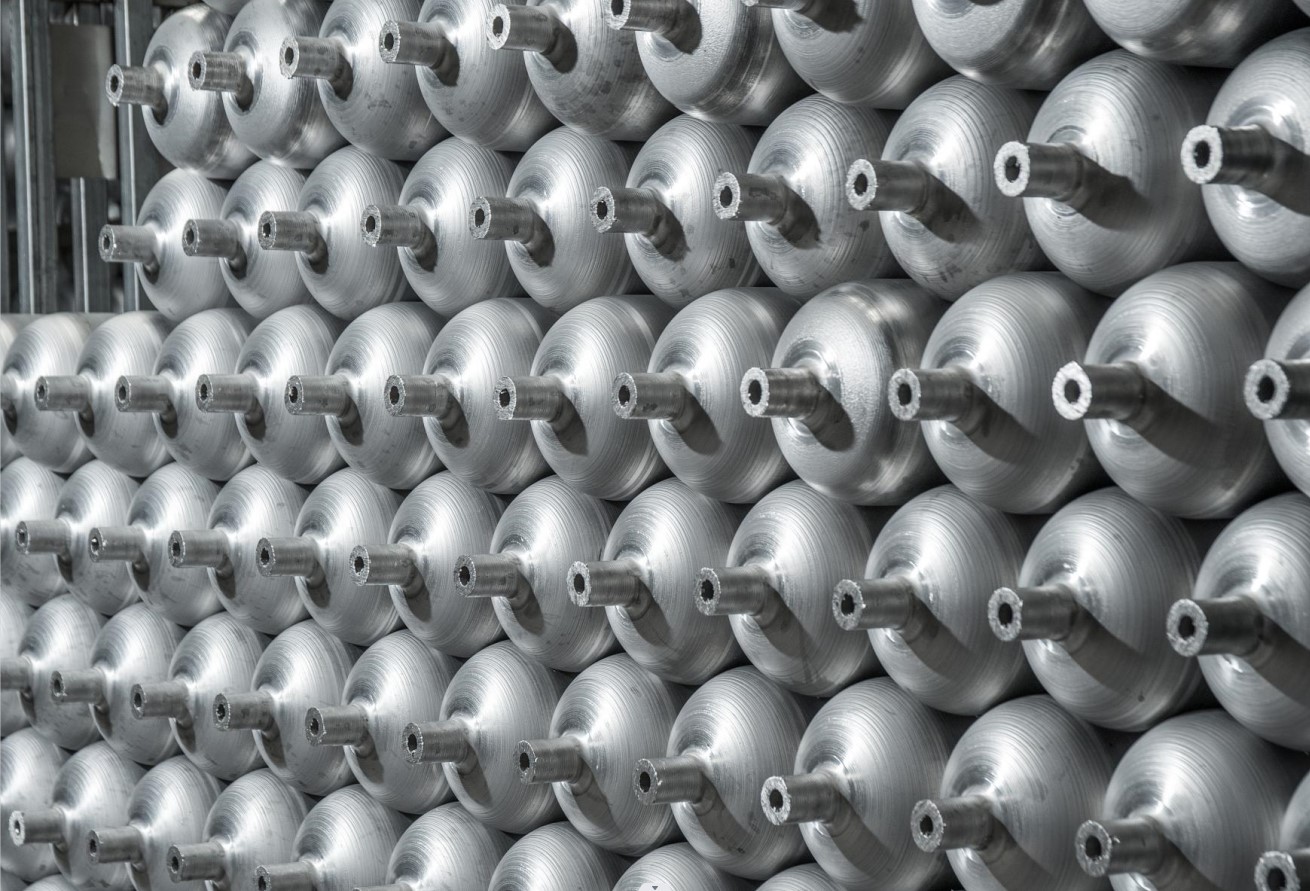

In the dynamic realm of composite cylinder production, the mechanical properties of liners play a pivotal role in ensuring durability and longevity. This article delves into the intricate details of how meticulous testing and examination of these mechanical properties contribute to the creation of cylinders that stand the test of time.

Understanding the Role of Liners: Liners form the core structure of composite cylinders, providing essential support and resilience. The mechanical properties, including tensile strength, hardness, and overall structural integrity, are critical factors in determining the robustness of these liners.

Tensile Strength Test: The journey begins with a comprehensive examination of the liners’ tensile strength. This test assesses the liner’s ability to withstand external forces and pressures, ensuring it can endure the rigorous conditions it may face in various applications such as firefighting, rescue operations, and industrial uses.

Hardness Testing: A deep dive into the hardness test reveals how it measures the liner’s resistance to deformation and wear. This property is crucial in guaranteeing that the liner can withstand the demands of its intended use, providing a foundation for the cylinder‘s overall reliability.

Mechanical Property Assessment: Beyond tensile strength and hardness, a holistic assessment of the liner’s mechanical properties takes place. This step evaluates the liner’s ability to maintain its structural integrity under pressure, ensuring it remains a sturdy and dependable component within the composite cylinder.

Quality Assurance through Rigorous Testing: The quality control process demands precision and consistency. By scrutinizing the mechanical properties of liners, manufacturers can identify any deviations or irregularities that might compromise the structural soundness of the cylinder. This rigorous testing ensures that every composite cylinder leaving the production line meets and exceeds industry standards.

Implications for End Users: For end users in firefighting, rescue operations, and other critical fields, understanding the meticulous examination of mechanical properties provides confidence in the reliability of the composite cylinders they depend on. These cylinders are not just products; they are engineered solutions built to endure the challenges of their respective applications.

Conclusion: As we unravel the complexities of examining the mechanical properties of liners in composite cylinder production, it becomes evident that each step in the testing process contributes to the overall reliability and durability of the final product. The commitment to excellence in understanding and enhancing these properties ensures that composite cylinders are not just components but steadfast guardians in critical operations, built to last.

Post time: Dec-04-2023