The world of emergency response and industrial safety relies heavily on reliable, efficient equipment. One crucial component is the breathing apparatus, a lifesaver for firefighters, first responders, and personnel working in hazardous environments. Traditionally, these apparatuses utilized steel cylinders to store the breathable air supply. However, a revolutionary shift is underway with the growing adoption of carbon fiber cylinders. This article explores the design and engineering advancements behind carbon fiber cylinders in breathing apparatus, highlighting the advantages they offer compared to their steel counterparts.

Strength Meets Efficiency: The Allure of the Strength-to-Weight Ratio

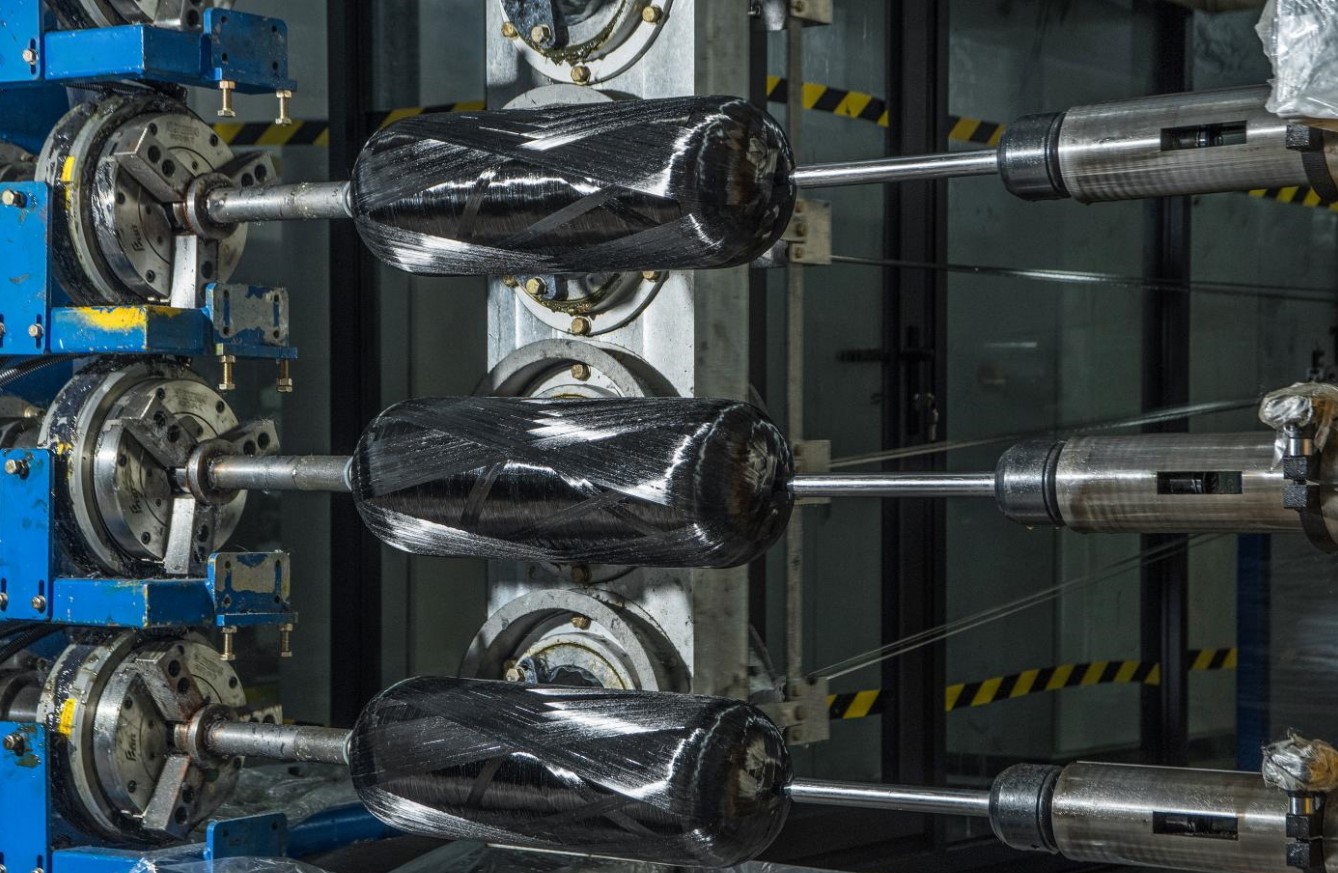

The primary driver for adopting carbon fiber cylinders in breathing apparatus lies in their exceptional strength-to-weight ratio. Carbon fibers, themselves incredibly strong and lightweight, are meticulously woven and embedded in a resin matrix to create a composite material. This results in a cylinder that boasts immense strength while staying remarkably light. For firefighters and other professionals carrying breathing apparatus for extended periods, this translates to a significant advantage.

Imagine a firefighter battling a blaze, navigating smoke-filled corridors while carrying heavy equipment. Every ounce counts. Replacing steel cylinders with their lighter carbon fiber counterparts reduces the overall weight of the breathing apparatus, leading to:

-Reduced Fatigue: Lighter equipment allows for better endurance and mobility, crucial for extended operations.

-Improved Maneuverability: The lighter weight enhances the wearer’s ability to navigate tight spaces or climb ladders with greater ease.

-Enhanced Safety: Reduced fatigue translates to improved decision-making and a lower risk of injury during critical situations.

This weight reduction also benefits industrial workers who rely on breathing apparatus for confined space entry or working in hazardous environments. Every pound saved translates to increased comfort and improved worker safety.

Pressure Vessel Design: Engineered for Safety and Reliability

The air supply within a breathing apparatus is stored at high pressure to ensure sufficient volume and flow for the wearer. This necessitates a robust pressure vessel design. Carbon fiber, with its exceptional strength-to-weight ratio, offers a perfect solution. Engineers can design carbon fiber cylinders to meet stringent safety standards for pressure containment while keeping weight to a minimum.

Here’s how careful design plays a vital role:

-Fiber Orientation: By strategically orienting the carbon fibers during the manufacturing process, engineers can optimize the cylinder’s strength to handle the internal pressure.

-Layup Techniques: The specific layering and arrangement of the fibers within the cylinder wall are crucial for ensuring uniform strength and preventing weak points.

-Material Selection: The choice of the resin matrix used to bind the carbon fibers also plays a role in pressure resistance and overall performance.

These meticulous design considerations ensure that carbon fiber cylinders in breathing apparatus can safely contain the pressurized air supply, providing a reliable and life-saving function for the wearer.

Beyond Strength: Addressing Impact Resistance for Unforeseen Situations

While carbon fiber excels in strength-to-weight ratio, impact resistance is another crucial factor to consider in a demanding environment like firefighting or industrial settings. The inherent stiffness of carbon fiber composites can make them susceptible to damage from blunt impacts. However, engineers are addressing this challenge through:

-Strategic Fiber Orientation: Specific fiber arrangements can improve the cylinder’s ability to absorb impact energy and distribute it more effectively.

-Toughened Resin Systems: Resins specifically formulated for enhanced toughness can improve the composite’s resistance to damage from impacts.

-Hybrid Designs: Combining carbon fiber with other impact-resistant materials like Kevlar can create a cylinder offering superior strength and resistance to accidents or debris strikes during emergency situations.

These advancements ensure that carbon fiber cylinders are not only lightweight and strong but also capable of withstanding the rigors of real-world use in demanding environments.

Adoption and Applications: Breathing Easier with Carbon Fiber

The benefits of carbon fiber cylinders are leading to their widespread adoption in breathing apparatus across various fields:

-Firefighting: As mentioned earlier, the weight reduction and improved mobility offered by carbon fiber cylinders are invaluable for firefighters.

-Industrial Safety: Personnel working in hazardous environments like confined spaces or chemical plants benefit from the lighter equipment and enhanced safety features of carbon fiber cylinders.

-Emergency Response: First responders and medical personnel utilizing breathing apparatus during rescue operations or medical emergencies experience greater comfort and improved mobility with lighter carbon fiber cylinders.

The Future Breathes Easy: Continuous Innovation in Design and Engineering

The development of carbon fiber cylinder design and engineering for breathing apparatus is an ongoing endeavor. Researchers are exploring several promising areas for further improvement:

-Nanotechnology Integration: Incorporating nanomaterials into the composite matrix can potentially enhance strength and impact resistance further.

-Sensor Integration: Embedding sensors

Post time: Apr-30-2024