Company Profile

Zhejiang Kaibo Pressure Vessel Co., Ltd. is an enterprise specializing in the design and production of carbon fibre fully wrapped composite cylinders. We’ve got B3 production license issued by AQSIQ -- the General Administration of Quality Supervision, Inspection and Quarantine, and passed the CE certification. In 2014, the company was rated as a national high-tech enterprise in China , currently has an annual production output of 150,000 composite gas cylinders. The products could be widely used in fields of firefighting, rescue, mine and medical application etc.

In our company, we have high-quality staff with respects on management and R&D, at the same time, we keep optimizing our process, pursuit of independent R&D and innovation , relying on advanced manufacturing technology and sophisticated production and testing equipment, it ensures the high quality of products and wins a good reputation.

Our company always adheres to the commitment of "quality first, continuous improvement, and customer satisfaction" and the philosophy of "keep progressing and pursuing excellence". As always, we look forward to cooperating with you and creating a mutual development.

System Guarantees Quality

We are meticulous in product quality control. In multi-variety and mass production, a strict quality system is the most important guarantee for stable product quality. Kaibo has passed the CE certification, ISO9001: 2008 quality system certification and TSGZ004-2007 certification.

High Quality Raw Materials

Kaibo has always insisted on selecting the best raw materials. Our fibres and resins are all selected from quality suppliers. The company has formulated strict and standardized purchase inspection procedures over raw material procurement.

Product Traceability Process

According to the system requirements, we have established a strict product quality traceability system. From the procurement of raw materials to the formation of finished products, the company implements batch management, tracks the production process of each order, strictly follows quality control SOP, conducts the inspection of incoming material , process and finished product, keeps records while ensuring that key parameters are in controlled during processing.

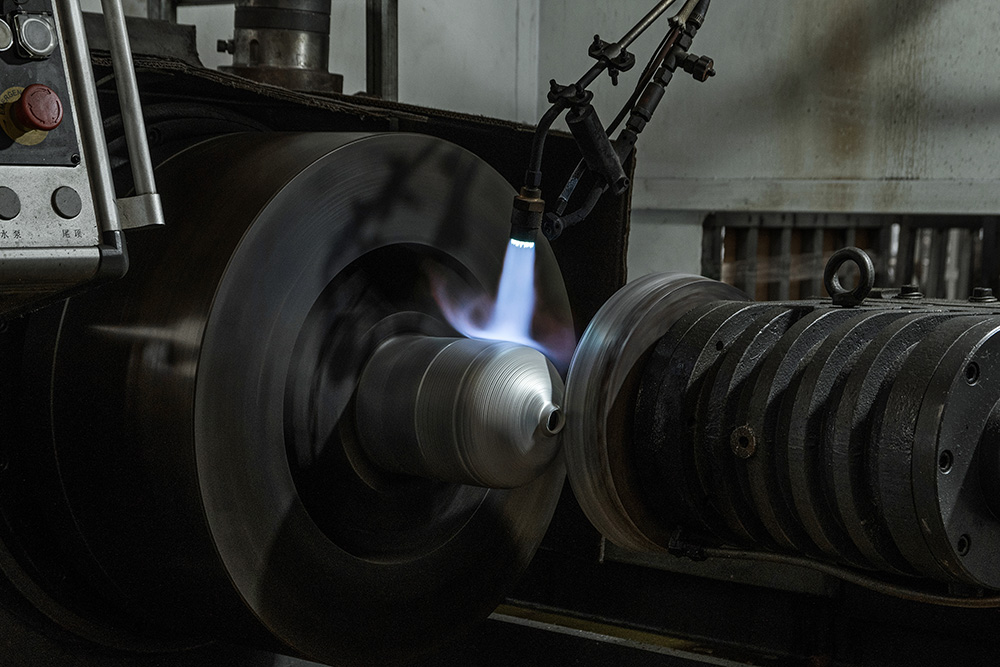

Quality Control Process

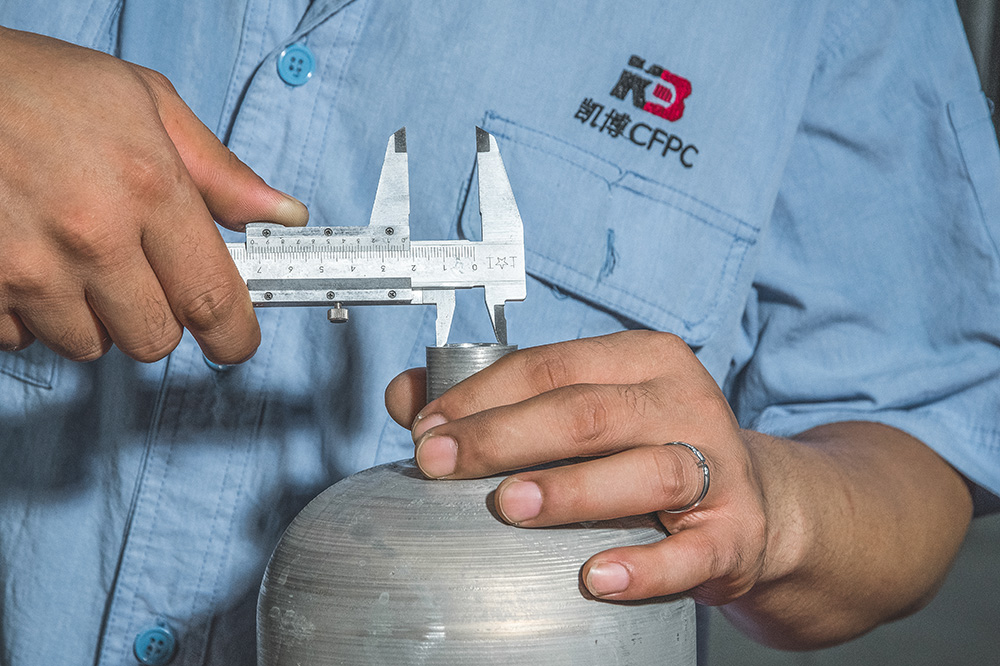

We conduct incoming material inspection, process inspection and finished product inspection according to the most strict requirements. Each cylinder needs to undergo the following inspections before it can be delivered to your hands

1. Fibre tensile strength test

2. Test of tensile properties of resin casting body

3. Chemical composition analysis

4. Liner manufacturing tolerance inspection

5. Inspection of inner and outer surface of liner

6. Liner thread inspection

7. Liner hardness test

8. Test of mechanical properties of liner

9. Liner metallographic test

10. Inner and outer surface test of gas cylinder

11. Cylinder hydrostatic test

12. Cylinder air tightness test

13. Hydro burst test

14. Pressure cycling test

Customer Oriented

We deeply understand the needs of customers, provide customers with the best products and services, and create value for customers to achieve a mutually beneficial and win-win cooperative relationship.

● Respond quickly to the market and provide customers with satisfactory products and services in the fastest time.

● Strengthen the customer-oriented organization and management, evaluate our work based on market performance.

● Take customer needs as the foothold of product development and innovation, and convert customer complaints into product improvement standards in the first place.

Corporate Culture

Create opportunities for employees

Create value for customers

Create benefits for society

Take every success as a starting point and pursue excellence

Pioneering

Innovation

Pragmatic

Dedication

Rigorous, united, innovative

Quality first, sincere cooperation, achieving a win-win situation

Technology Pioneer

People Oriented

Sustainable Development

Innovative concept

Innovative technology

Constantly surpassing

Concentrate on enabling customers to get access to the most valuable products